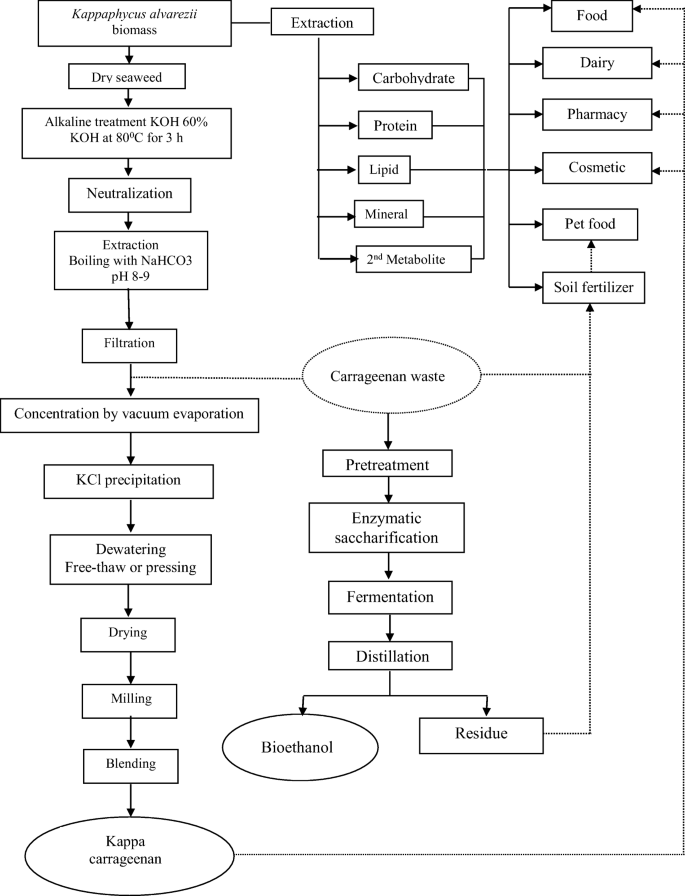

carrageenan production process

Producing countries include argentina canada chile denmark france japan mexico morocco portugal north korea south korea spain russia and the usa. This recovery process is difficult and expensive relative.

Lecture Xviii Charged Ps S Carrageenan Agar Ppt Download

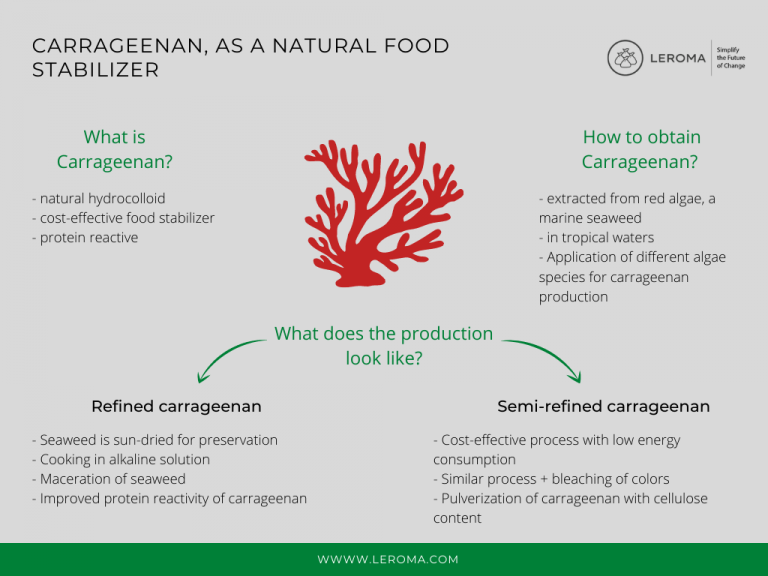

Semi refined carrageenan is also known as processed eucheuma seaweed with the E number E407a.

. For the sake of convenience we will refer to these as. It also provides synergy with dairy proteins suspends and stabilizes fat protein and cocoa particles while improving mouthfeel. Carrageenan is an important production used in the cosmetic industry because of its physical and functional ability and antioxidant activity.

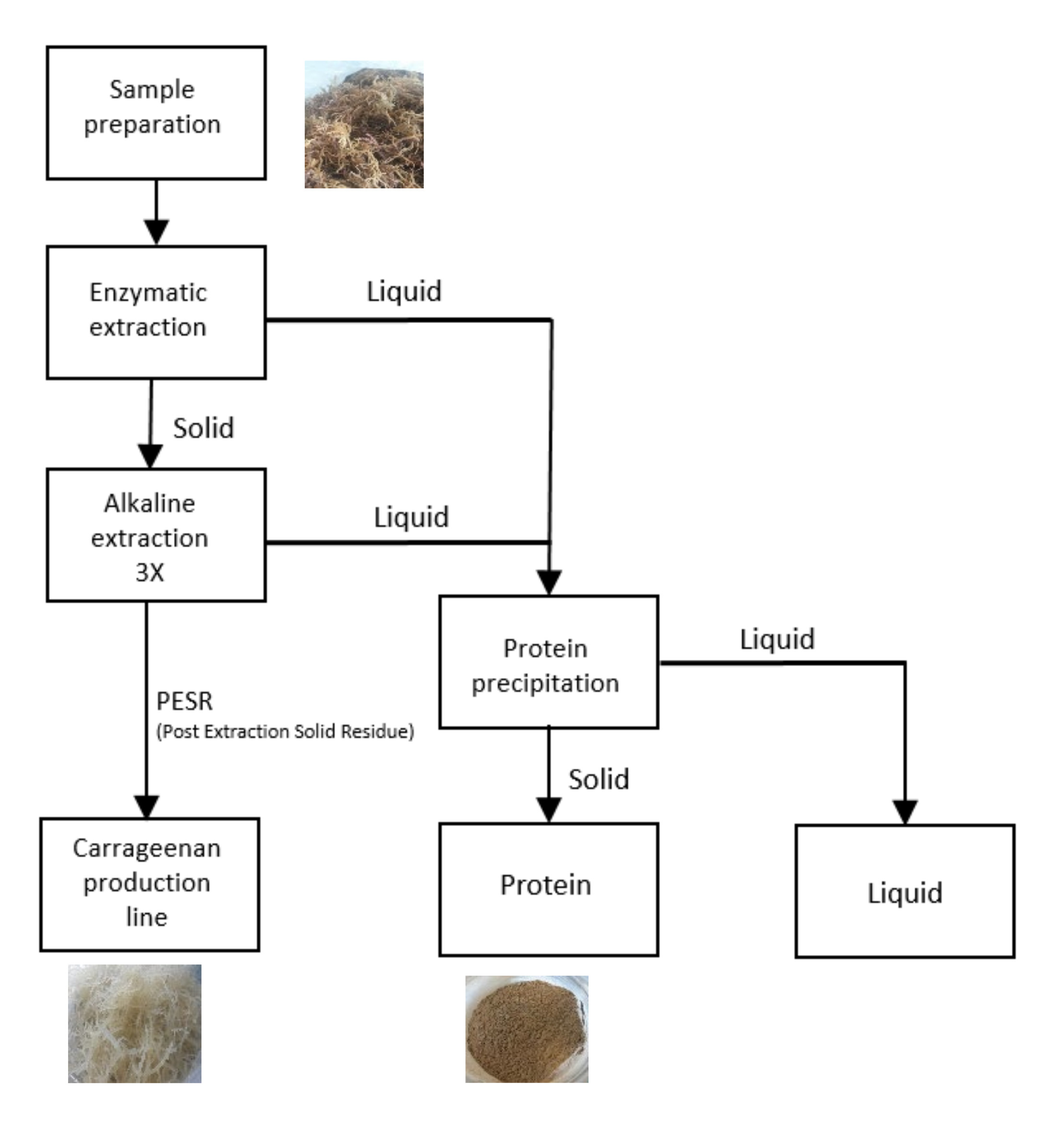

IOTA elastic gel thermo-reversible no syneresis thixotropic. The methods of the present invention prepare carrageenan products from processed seaweed material having a solids content of less than 25 by. The production of semi refined or refined kappa and iota are similar t he following are the brief kappa carrageenan manufacturing process.

Carrageenan synthesis by the treatment of OH from red algae. Commercial processing covers the 1 extraction of higher value substances from agricultural and fishery raw materials through bioprocessing. The study covers all the requisite aspects that one needs to know while making a foray into the carrageenan industry.

Preparation of edible film from carrageenan has been studied in this research. This includes the heat necessary to digest and cook the seaweed to concentrate the filtrate in evaporators to dry the coagulum and in the case of alcohol precipitation to recover the spent alcohol by. In the production of SRC the washed and cleaned seaweed is heated in an alkaline solution of potassium hydroxide for about two hours in order to increase the gel strength of the Carrageenan in the seaweed and at the same time dissolve any soluble protein carbohydrate and salts without dissolving the Carrageenan.

This production cost analysis report by Syndicated Analytics is the result of a comprehensive examination of the carrageenan manufacturing process. Primarily wild-harvested genera such as chondrus furcellaria gigartina sarcothalia mazzaella iridaea mastocarpus and tichocarpus are also mainly produced as carrageenan raw materials. Last it will be chopped then dried using hot air to create the kappa refined carrageenan end product.

Then the heating process will be done to create the kappa carrageenan from the material but there is also celluloses created during the making process. In the original method - the only one used until the late 1970s-early 1980s - the carrageenan is extracted from the seaweed into an aqueous solution the seaweed residue is removed by filtration and then the carrageenan is recovered from the solution eventually as a dry solid containing little else than carrageenan. Carrageenan can be classified according to its structure and chemical properties or according to its production process.

To get rid all of the celluloses then centrifugation process as well as filtration process is done. The economics of extraction processes are strongly affected by the cost of the energy required to bring the carrageenan into solution and subsequently to recover it in dry form. Semi Refined Flow Chart.

After the alkali treatment and water washing the product is. Next is the soaking process using alkali solution which usually is the Potassium hydroxide that is in 5 to 8 of the overall amount. But because of those processes then the end product also contains more potassium chloride compared to other type of carrageenan.

In a flan product carrageenan will form the necessary gel structure control the basic product texture react with and stabilize the milk protein provide uniform stabilization and improve flavor release. Or 2 conversion of agricultural and fishery products or wastes to a form ready for further processing. Carrageenan production goes back many decades and only recently with the introduction of new weed sources as there been any major developments in the processes involved.

The manufacture of carrageenan as a commercial processing activity can be considered among the preferred activities listed in the IPP. But it is still have the same if not better ability when used as ingredient in several products. Alcohol Precipitation KCl Precipitation or gel press Danisco process.

There are four basic processes used for the production of carrageenan. Carrageenan also offers some in-process advantages because it has a comparatively low viscosity in solution before it gels. It is obtained through the following process.

Carrageenan are water soluble polysaccharides extracted from red seaweeds with thickening stabilizing and gelling properties. It is based on the latest economic data and presents exhaustive insights about the primary process flow raw. Cargill offers one of the widest ranges of commercially available carrageenan employing proven production processes.

The edible films were made by phase inversion method with various carrageenan concentrations of 1 125 15. Most of the carrageenan derivatives consider for cosmeceutical production and isolated from red seaweeds. Structure and Chemical Property KAPPA rigid and brittle gel thermo-reversible high gel strength showing syneresis.

Manufacturing Process Of Bioplastic From Seaweeds Source Download Scientific Diagram

Carrageenan Manufacturing Process Flow Chart Re Produced From Download Scientific Diagram

Carrageenan Foods Additives Is Carrageenan Safe

Sequential Acid And Enzymatic Hydrolysis Of Carrageenan Solid Waste For Bioethanol Production A Biorefinery Approach Springerlink

Pdf Extraction And Isolation Of Kappa Carrageenan From Red Seaweeds Semantic Scholar

Process Flow Sheet For Preparation Of Semi Refined Carrageenan Download Scientific Diagram

Foods Free Full Text Multi Extraction And Quality Of Protein And Carrageenan From Commercial Spinosum Eucheuma Denticulatum Html

Leroma Carrageenan A Natural And Versatile Food Stabilizer

Carrageenan Production Methods

Conventional Extraction Method Of Refined Carrageenan Rc And Download Scientific Diagram

5 Flow Chart Of Semi Refi Ned Carrageenan Production Where The Download Scientific Diagram

Re Evaluation Of Carrageenan E 407 And Processed Eucheuma Seaweed E 407a As Food Additives 2018 Efsa Journal Wiley Online Library

Pdf Preparation Of Semi Refined K Carrageenan Recycling Of Alkali Solution And Recovery Of Alkali From Spent Liquor

Carrageenan 101 Mcpi Carrageenan For The World

Carrageenan Manufacturing Process Flow Chart Re Produced From Download Scientific Diagram

Comments

Post a Comment